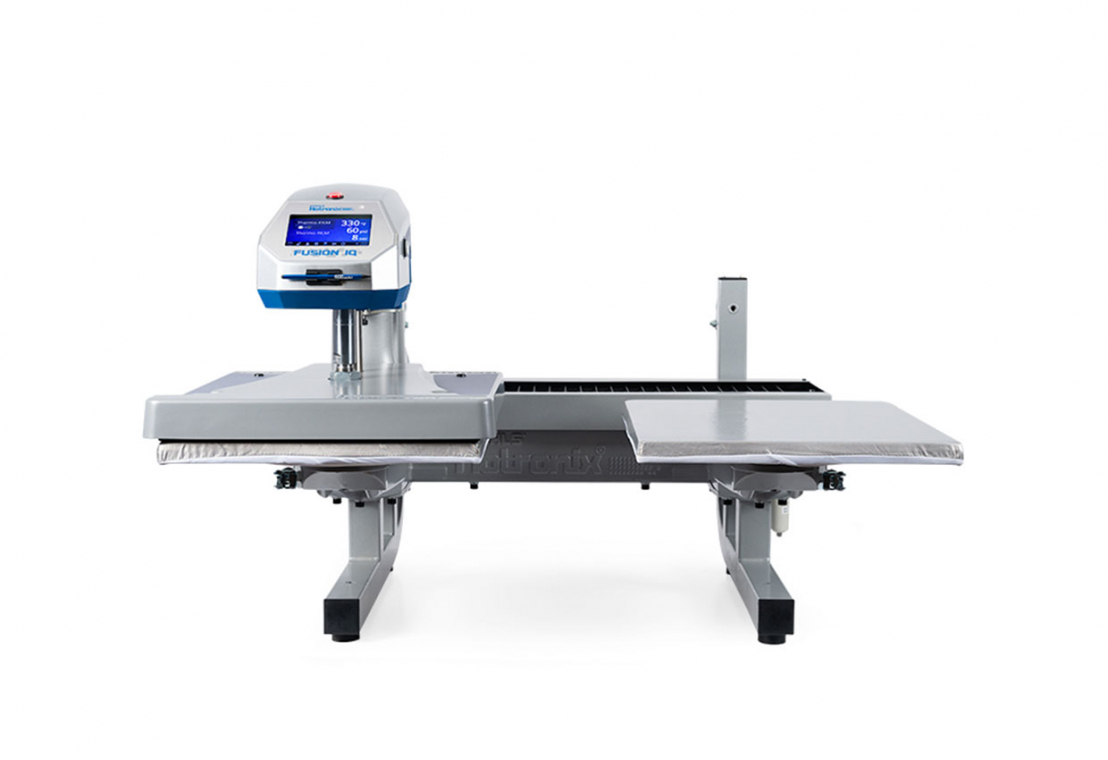

Hotronix® Dual AirFusion IQ®

Double the performance

This heat press has two separate base plates which ensure an even more efficient and varied workflow. This innovative concept allows different settings of time, contact pressure and, if desired, temperature per contact surface. Reduce your production time by half with this press. The A and B workstations may be controlled together or separately.

You can save and call up presets conveniently and easily via the touch screen. Each Hotronix® Dual Air Fusion IQ® is supplied with several accessories: A foot pedal that allows you to move the head of the press, two non-stick slipcovers and the optional ProPlace IQ™ projection alignment system. These add-ons can have a huge impact on the efficiency of your work.

The heating plate of your Hotronix® Dual Air Fusion IQ® can be moved back and forth using the foot pedal. This allows the user to continue working with both hands while the head of the press is already on the next textile. The non-stick protective covers not only protect your base plates from soiling, but also allow you to put your textiles on and take them off more quickly and easily. For example, you can let work surface A do the pre-treatment while work surface B is used to finish your product. This new development will improve your work by significantly saving time and increasing the quality of your prints.

The Fusion IQ® controller of the Hotronix® Dual Air Fusion IQ® makes it possible to achieve perfect results with every pressure.

We recommend the use of Hotronix® Dual AirFusion IQ® only in combination with the Panther 100 compressor.

Your benefits at a glance

Stahls' Warranty

Specifications

- 240V, 15 Amp, 3500W

- 115 cm (L) x 115 cm (W) x 86 cm (H)

- Net Weight 120 kg

- Gross Weight 200 kg

Flexible

Heating plate

Technology

Quality

Downloads

Hotronix® Dual AirFusion IQ®

Give us a call, we will be happy to advise you: +49 (0) 68 31 / 97 33 0

or